The objective of this line is the development of a methodology based on simulation software for the design of cells and robotic and/or automated manufacturing lines, identifying the necessary systems, technologies and tools that allow for the optimization of their performance, as well as their optimal layout taking into account the cycle time, safety, ergonomics and available space requirements applicable in each case.

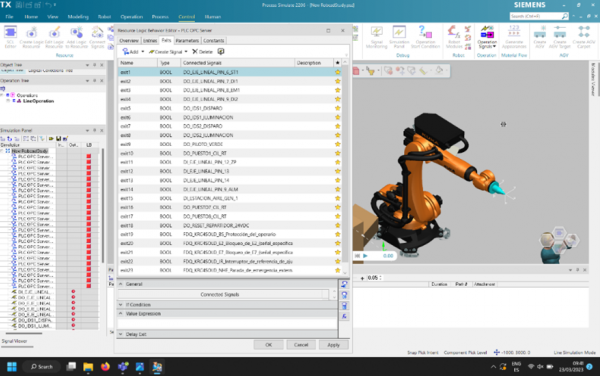

By creating a digital twin of manufacturing cells, it will be possible to simulate and analyze the manufacturing processes before and after their automation, creating scenarios to optimize and validate the design obtained, including logic at the PLC level and programming of the robots.

Thus, in this research line, the feasibility of robotization or automation of different processes in shipbuilding will be analyzed. For this, it is necessary to use 3D simulators that allow for the design and development of robotic work stations. It will also be necessary to redesign the process itself to adapt it to this new configuration. The proper choice of sensors for information collection and subsequent control is also important for this line.